Custom Metal Roofing

Covering Hawaiʻi homes and businesses since 1963

Covering Hawaiʻi homes and businesses since 1963

It’s hard to settle on a single reason why HPM’s Custom Metal Roofing reigns supreme. Is it the innovative construction technology, the years of experience we’ve spent perfecting roofing design, or the exceptionally strong, sustainable materials we use to manufacture each roof? Maybe it’s the meticulous installation process and the exceptional service that make our metal roofing supply customers so happy. Whatever the cause, one thing’s for certain: You’ll have a roof that outlasts expectations.

We’ve been a leader in metal roofing for more than 60 years, offering extremely competitive pricing, expert roofing personnel and the equipment and systems to provide accurate, on-time delivery.

Our metal roofing panels are made with the highest recycled content of steel and aluminum, allowing for metal roofing and other metal construction products to be routinely included on listings of green and sustainable building materials.

Our Custom Metal Roofing features Durapon70 heat-reflective finish that reflects more of the sun’s rays to keep your home cool.

Choose from many different Custom Metal Roofing colors, including metallic and exotic finishes. Durapon70 provides excellent color retention and resistance to chalking and fading.

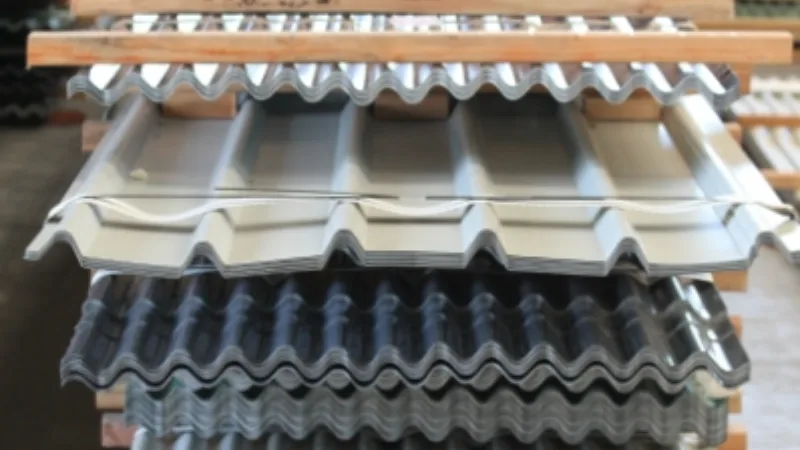

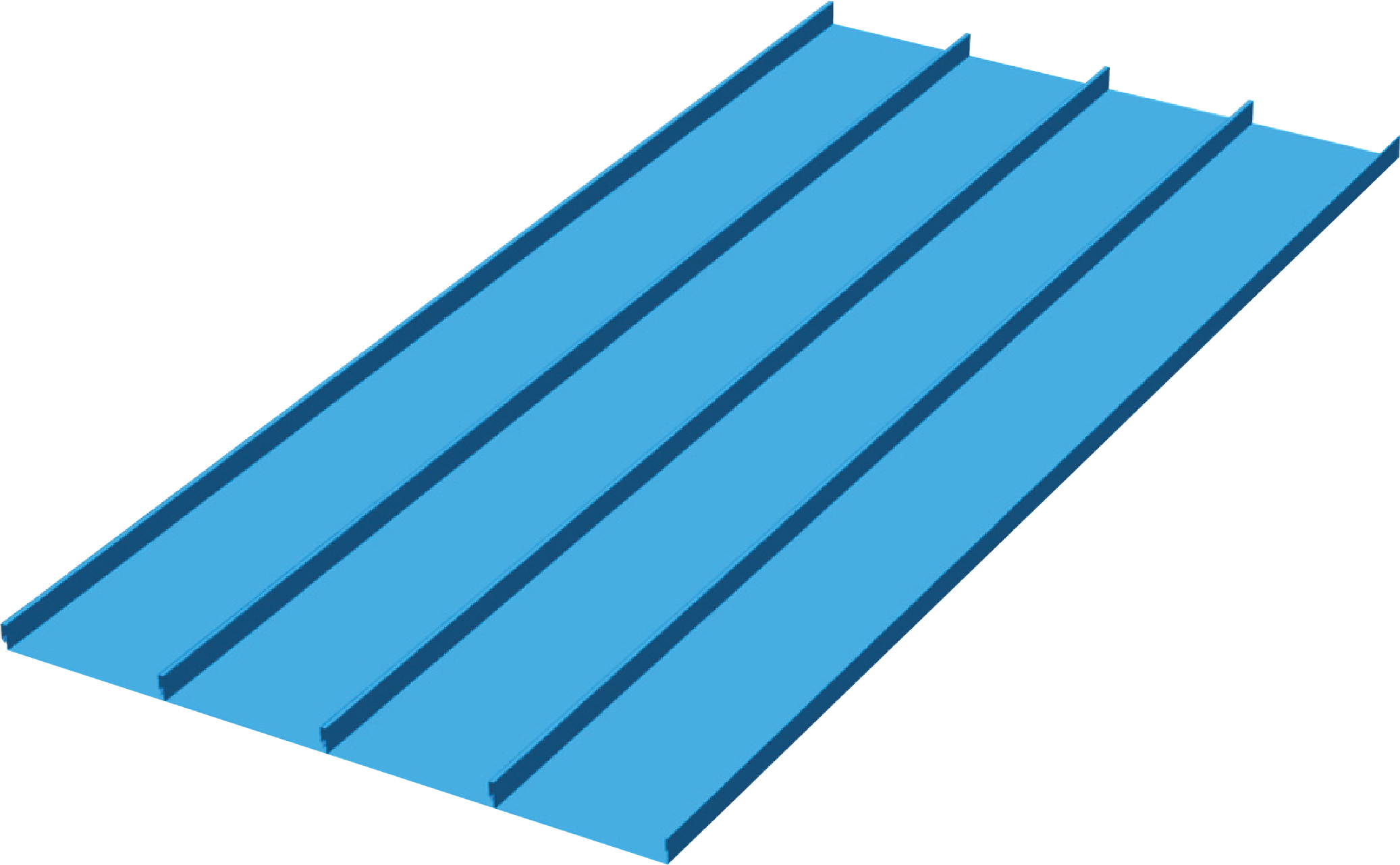

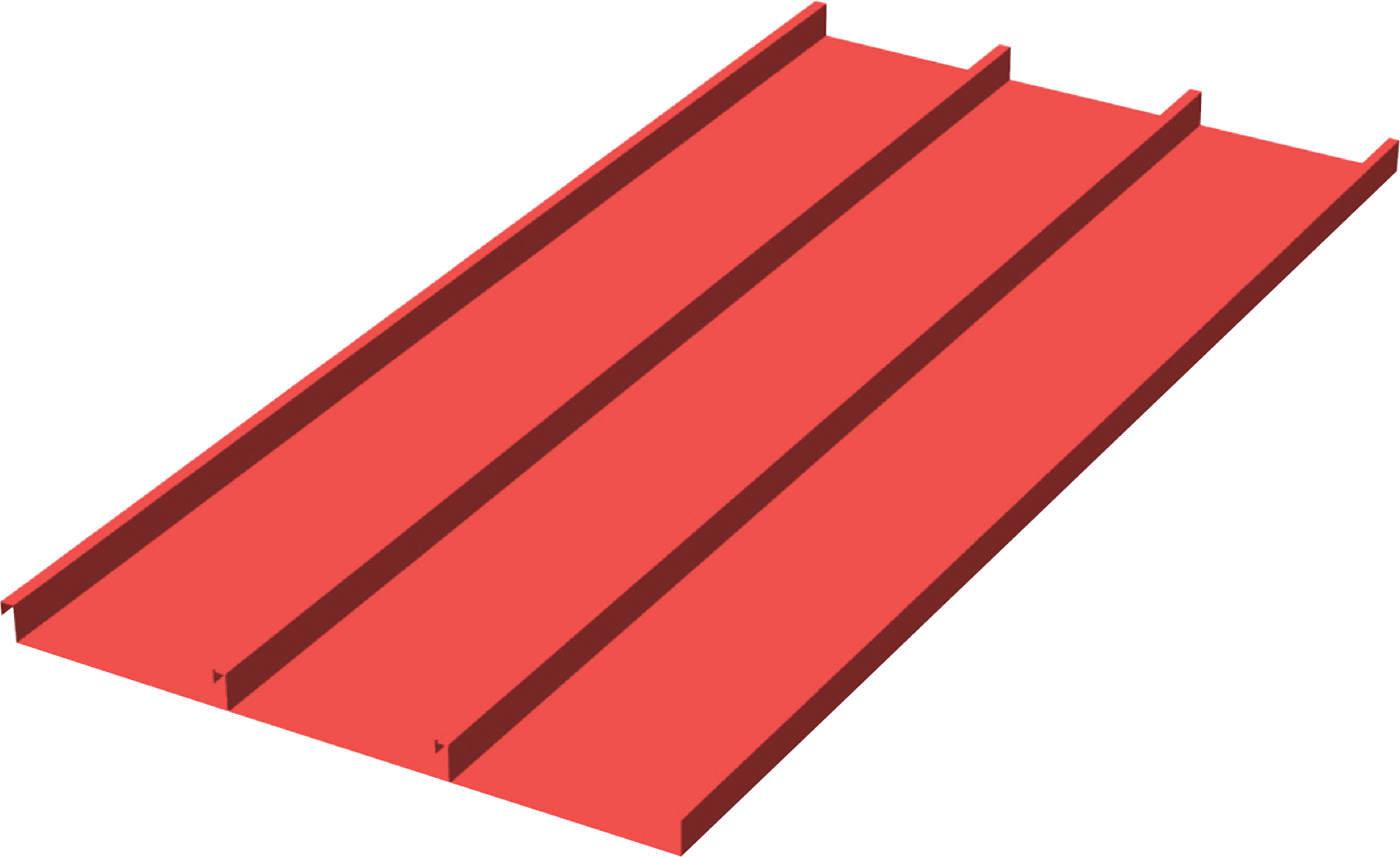

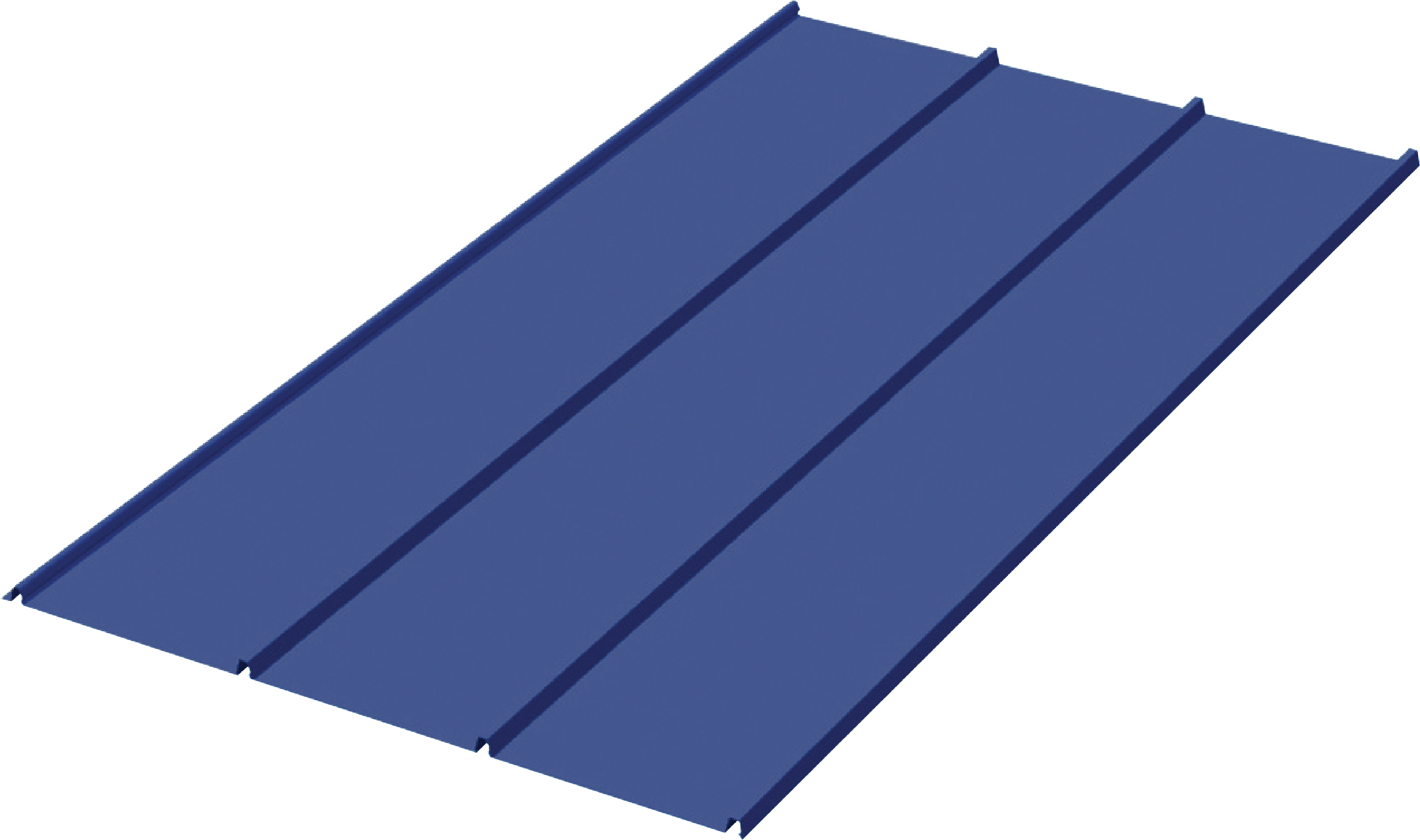

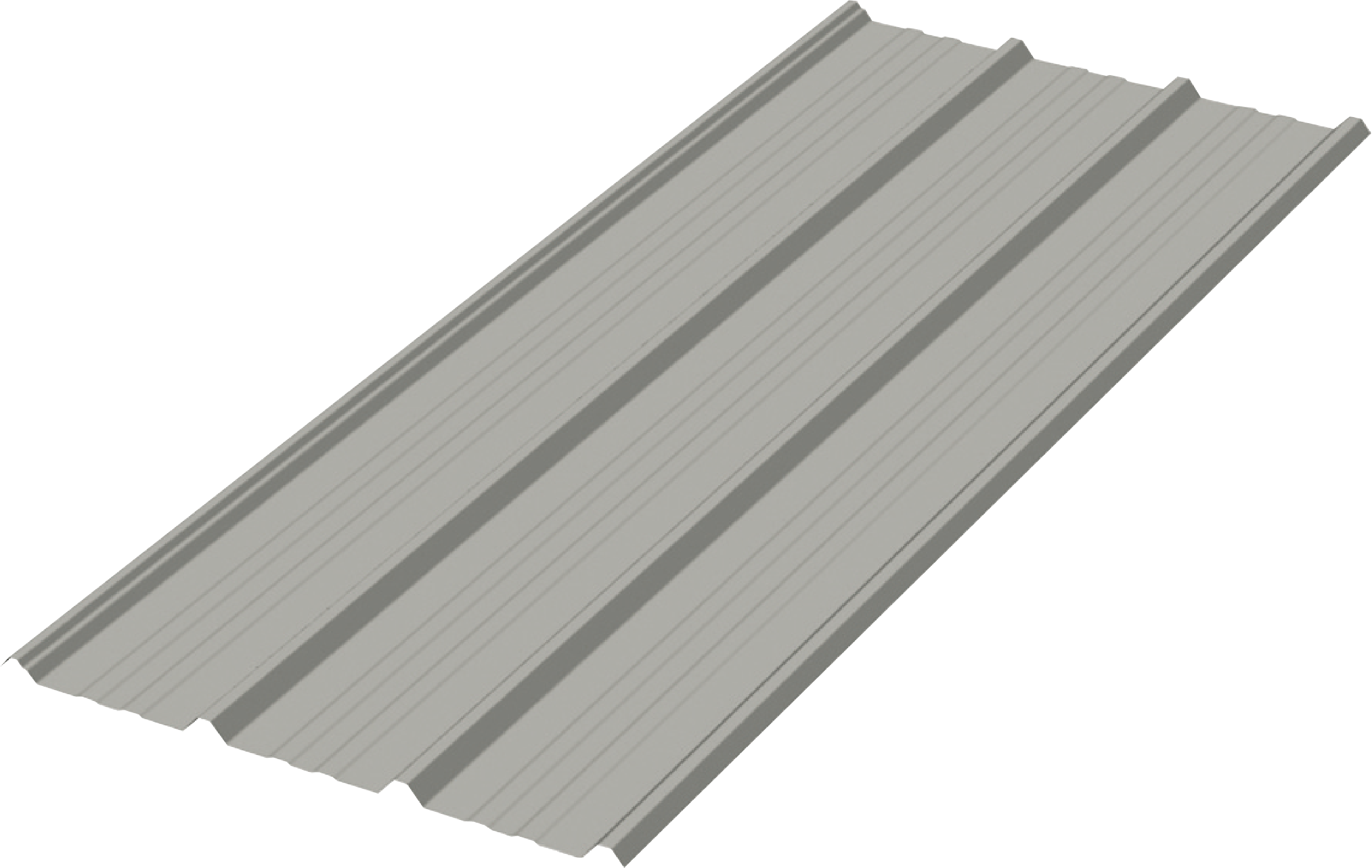

Fasten-through panels are manufactured to your exact lengths and specifications at HPM’s production facility in Keaau and delivered to your jobsite. They’re fastened with exposed color-matched screws that penetrate the metal roofing and secure to the purlin or sheathing. In general, fasten-through panels are less expensive than Standing Seam panels.

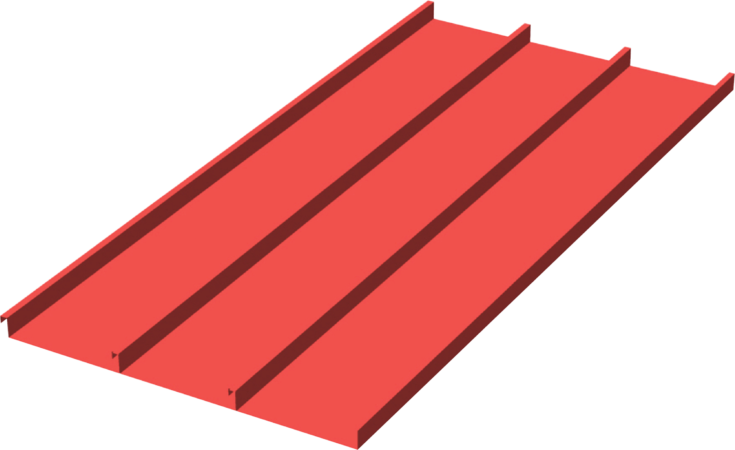

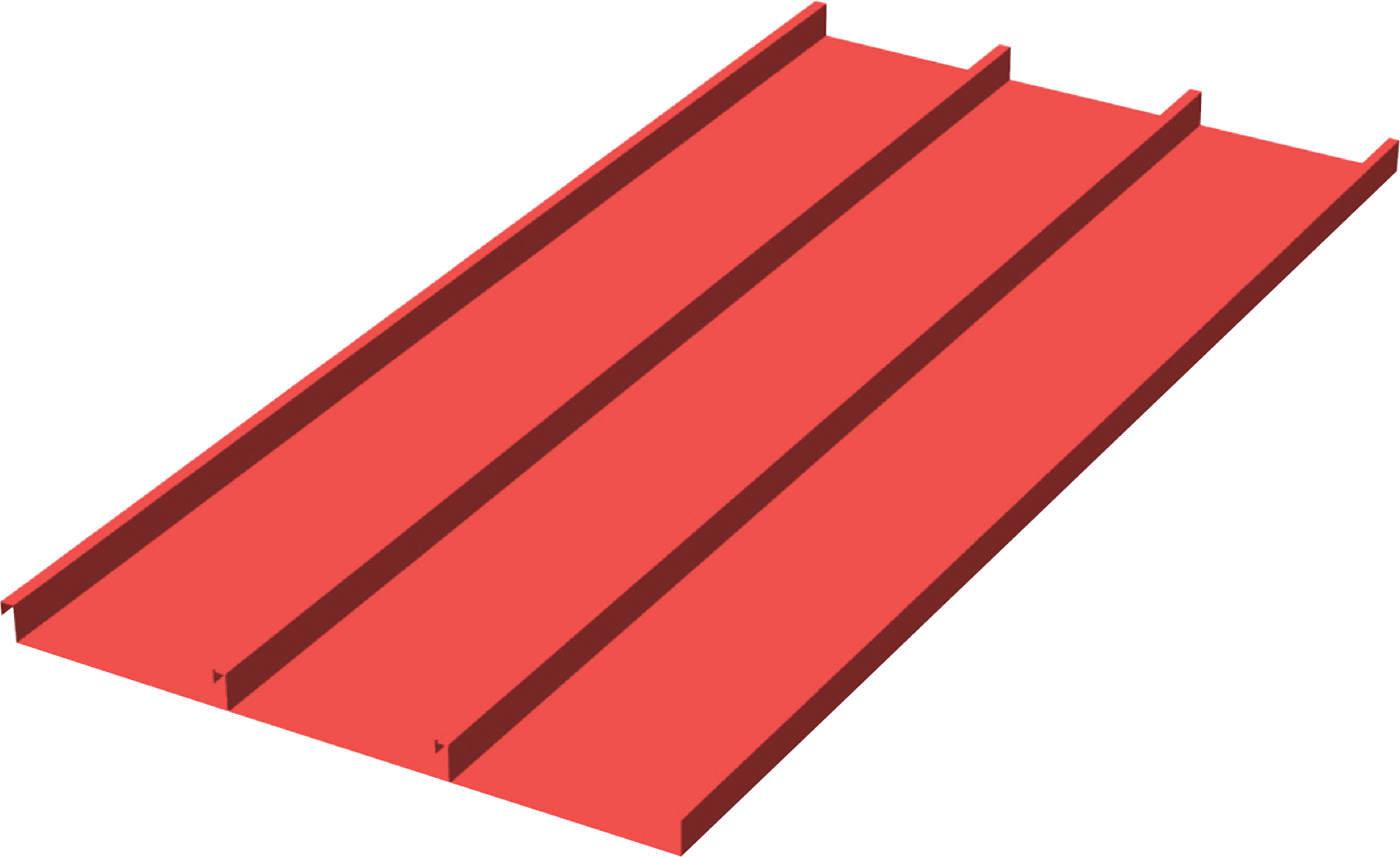

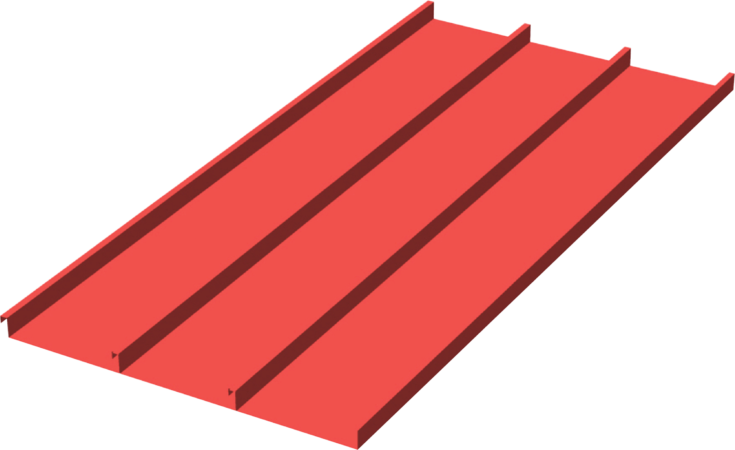

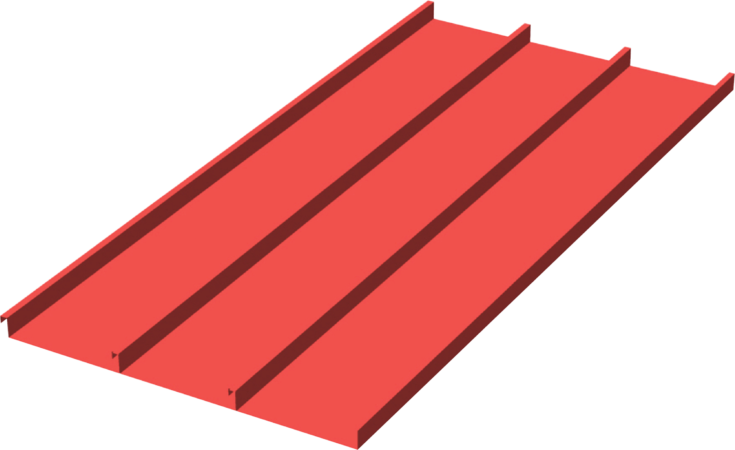

HPM manufactures the Standing Seam right on your jobsite using a portable roll-former. This enables each panel to be produced to exact measurements as specified in the field as the contractor installs. Standing Seam panels are fastened using screws or concealed clips, and the ribs are engaged by either snapping together or mechanically seaming. Curved and tapered treatments are available to match unique architectural designs. Photovoltaic solar panels can be easily installed on standing seam roofing using clips instead of penetrating screws.

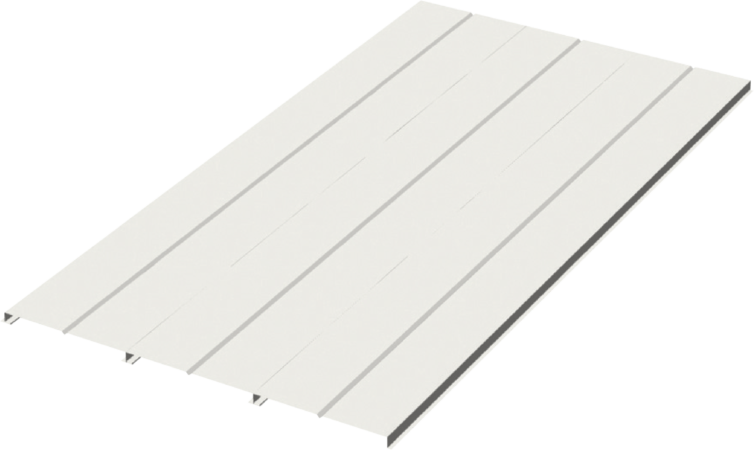

• 1” profile height

• 14” panel widths

• Custom panel lengths

• Zincalume aluminum-zinc coated steel available in 24 or 22 gauge (special order)

• Aluminum alloys availabe in .032” or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Custom panel face treatments (striations, stiffening ribs). Striations recommended to minimize oil canning.

• Apply over decking or open framing

• On-site manufacturing

• Optional venting available

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

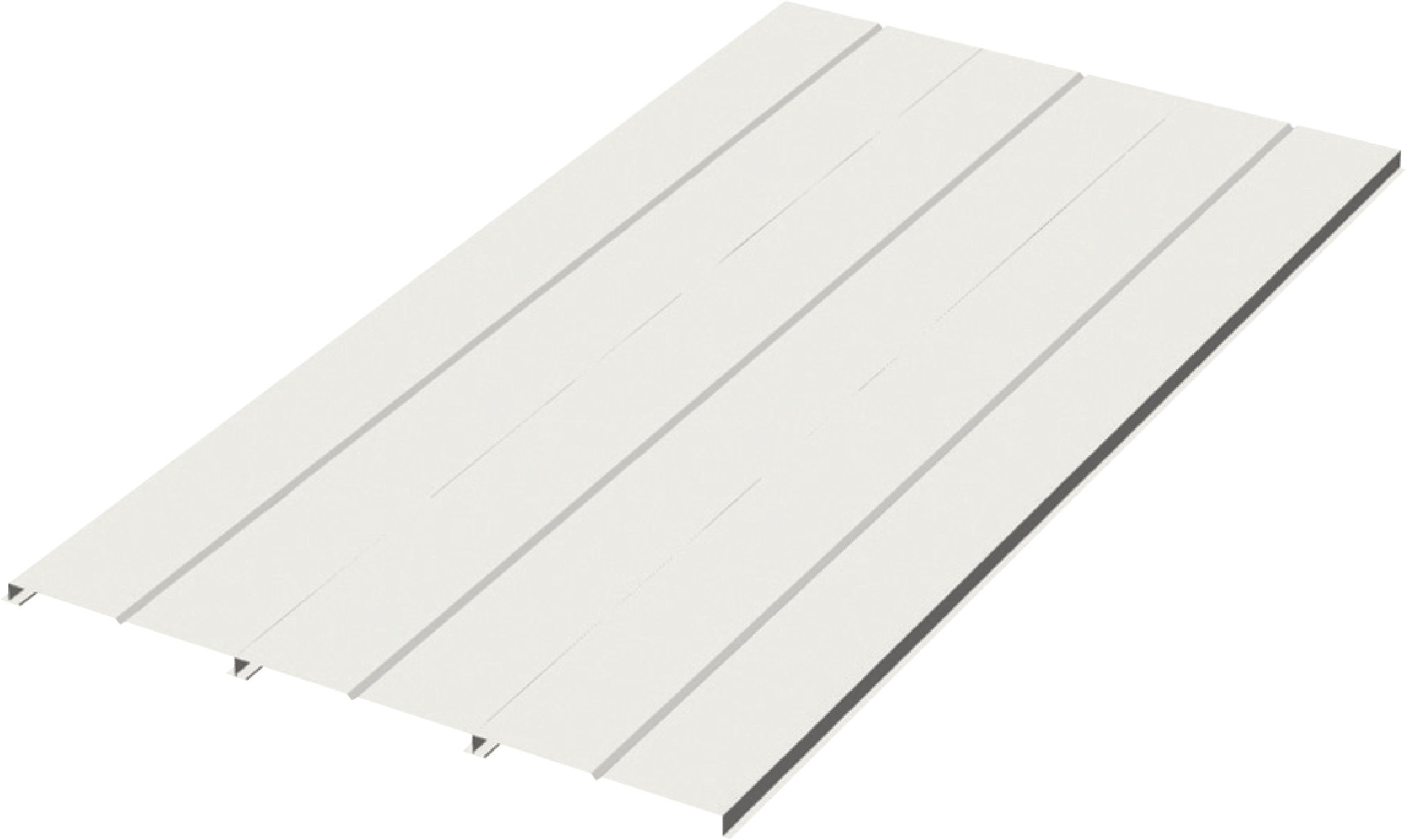

• 1¾” nominal rib height

• 12” & 16” Standard - Other widths available by special order

• Minimum recommended slope 3:12

• Custom panel lengths

• Snap seam installation

• Zincalume aluminum-zinc coated steel available in 24 or 22 guage (special order)

• Aluminum alloys available in .032” standard or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Special order copper in 16 or 20 ounce

• Custom panel face treatments (striations, stiffening ribs). Striations recommended to minimize oil canning

• Apply over decking or open framing

• On-site manufacturing

• UL 580 class 90 Wind Uplift rating

• ASTM E1592, E1646 & E1680 performance testing (with field applied seam sealant)

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

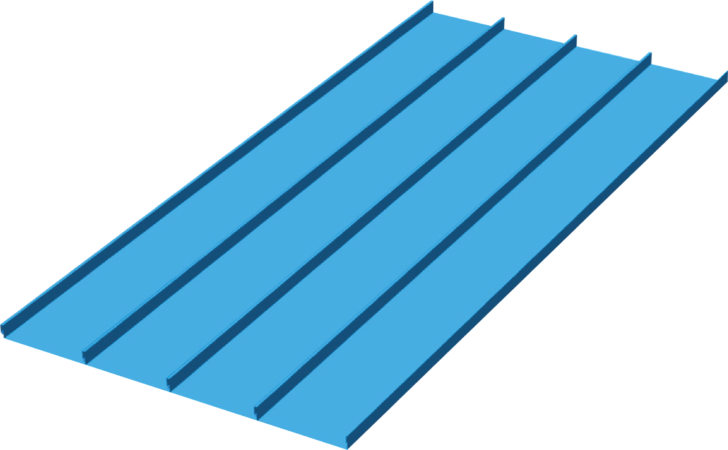

• 2” normal rib height

• 12-1/4” Standard - Other widths available by special order

• Structural design (can be installed on open perlins)

• Custom panel lengths

• Mechanical seam installation (double lock seams)

• Zincalume aluminum-zinc coated steel available in 24 or 22 gauge (special order)

• Aluminum alloys available in .032” or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Special order copper in 16 or 20 ounce

• Custom panel face treatments (striations, stiffening ribs). Striations recommended to minimize oil canning.

• On-site manufacturing

• UL 580 Class 90 Wind Uplift rating & ASTM E1592 performance testing

• Air & water infiltration resistance to E1646 & E1680 (with field applied seam sealant)

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

• 2” normal rib height

• 12” Standard - Other widths available by special order

• Structural design (can be installed on open purlins)

• Custom panel lengths

• Mechanical seam installation (double lock seams)

• Zincalume aluminum-zinc coated steel available in 24 or 22 gauge (special order)

• Aluminum alloys available in .032” or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Special order copper in 16 or 20 ounce

• Custom panel face treatments (striations, stiffening ribs). Striations recommended to minimize oil canning.

• On-site manufacturing

• UL 580 Class 90 Wind Uplift rating & ASTM E1592 performance testing

• Air & water infiltration resistance to E1646 & E1680 (with field applied seam sealant)

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

• 1-1/2” normal rib height

• 14” Standard - Other widths available by special order

• Structural design (can be installed on open purlins)

• Custom panel lengths

• Mechanical seam installation (double lock seams)

• Zincalume aluminum-zinc coated steel available in 24 or 22 gauge (special order)

• Aluminum alloys available in .032” or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Special order copper in 16 or 20 ounce

• Custom panel face treatments (striations, stiffening ribs). Striations recommended to minimize oil canning.

• On-site manufacturing

• UL 580 Class 90 Wind Uplift rating & ASTM E1592 performance testing

• Air & water infiltration resistance to E1646 & E1680 (with field applied seam sealant)

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

• 1” normal rib height

• 14” Standard - Other widths available by special order

• Custom panel lengths

• Snap seam installation (clip-less, non-mechanical)

• Zincalume coated steel available in 24 or 22 gauge (special order)

• Aluminum alloys available in .032” or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Special order copper in 16 or 20 ounce

• Custom panel face treatments (striations, stiffening ribs). Striations recommended to minimize oil canning.

• Apply over solid decking

• On-site manufacturing

• ASTM E1592 performance tested

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

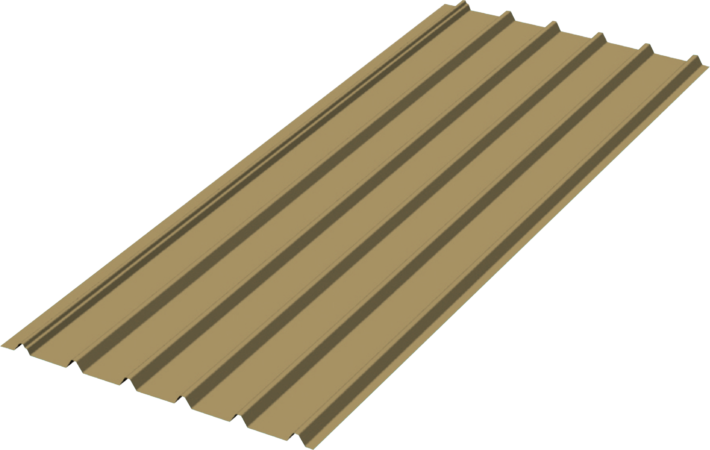

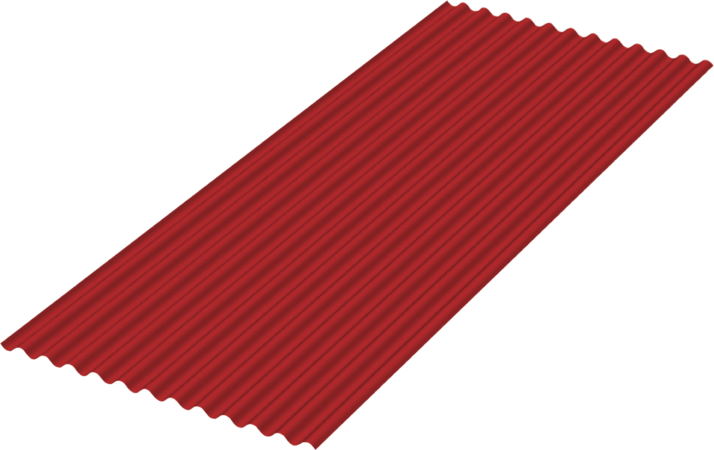

• Efficient 32-1/2” coverage

• Minimum recommended slope 3:12

• Bearing leg and anti-siphon groove

• Structural design (can be installed on open purlins)

• Custom panel lengths to 42’

• Zincalume steel AZ50/55 aluminum-zinc coated steel available in 26, 24 or 22 gauge (special order)

• Aluminum alloys available in .032” standard or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Tested to ASTM E1592 for wind uplift resistance

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

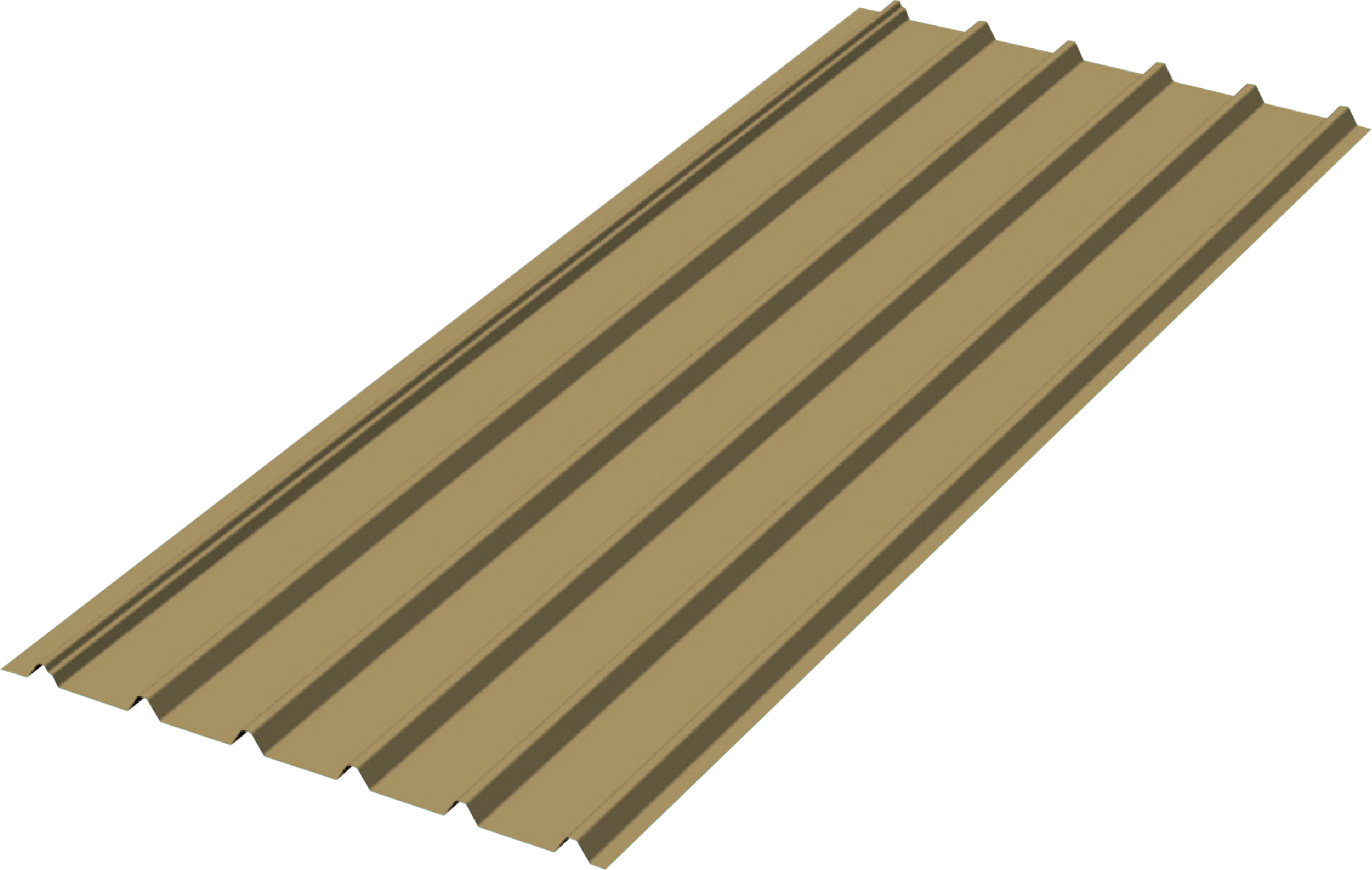

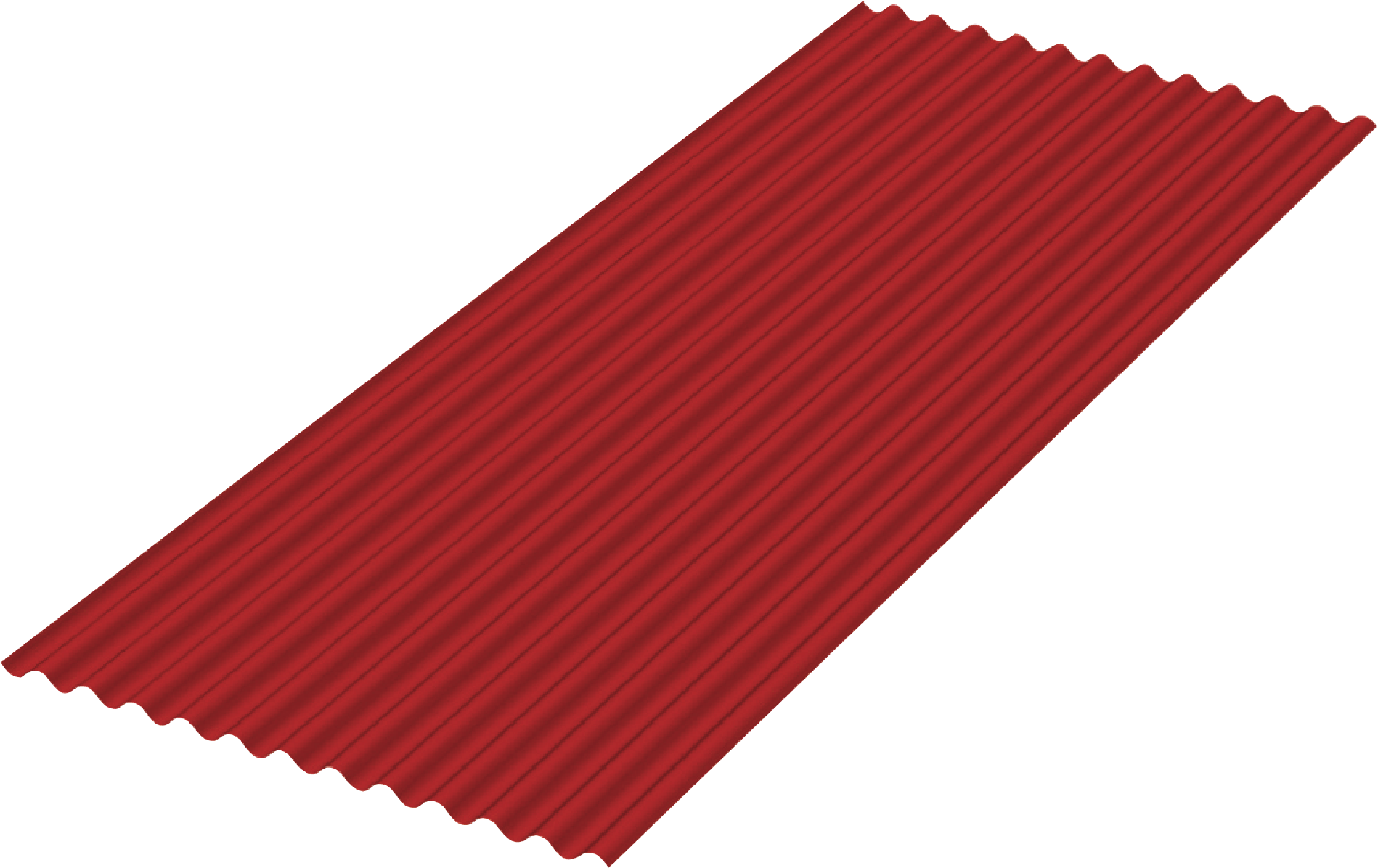

• Efficient 36” coverage

• Bearing leg and anti-siphon groove

• Minimum recommended slope 3:12

• Structural design (can be installed on open purlins)

• Custom panel lengths to 42’

• Similar skylight panels available (not to be end lapped)

• Zincalume AZ50/55 aluminum-zinc coated steel available in 26, 24 or 22 gauge (special order)

• Aluminum alloys available in .032” standard or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Tested to ASTM E1592 for wind uplift resistance

• Tested for air and water resistance to ASTM E1680 and E1646 (with field applied seam sealant)

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

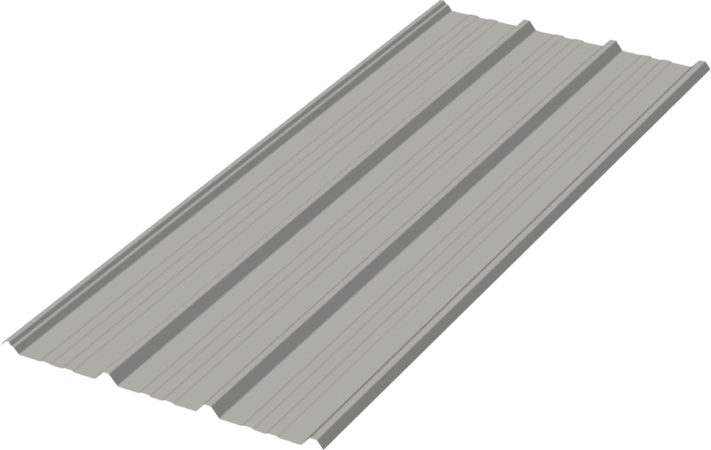

• Efficient 29-1/3” or 32” coverage depending on application

• Minimum recommended slope 3:12

• Structural design (can be installed on open purlins)

• Custom panel lengths to 42’

• Available skylights (similar profile)

• Zincalume steel AZ50/55 aluminum-zinc coated steel available in 26, 24 or 22 gauge (special order)

• Aluminum alloys available in .032” standard or .040” (special order)

• Standard or custom Durapon 70 factory color finishes

• Tested to ASTM E1592 for wind uplift resistance

• Tested for air and water resistance to ASTM E1680 and E1646 (with field applied seam sealant)

NOTE: PANEL WIDTH IS NOMINAL - VARIANCE +\- 1/8”

HPM offers quality rain gutter products and installation services on Maui, Moloka‘i, and Lānaʻi. Our selection includes continuous gutters made from copper and aluminum, gutter guard screens, and downspouts. Select from various profiles and colors of continuous rain gutters, including 5-inch K-style continuous gutters, 7-inch K-style continuous gutters, and 6-inch half-round continuous gutters. Factoid: We are also one of the only local companies to offer 8-inch half-round continuous gutters.

HPM is Hawaiʻi's exclusive fabricating distributor of Elevate's metal roofing systems. Elevate offers long-term 20-year metal roofing warranties to ensure your protection for commercial projects for years to come.

Our building experts are available to partner with you on your current or future project.

Our building experts are available to partner with you on your current or future project.

Contact us for a free consultation and quote.

Contractor License BC-37829

Receive the latest in HPM news, products, exclusive deals and more!